What is VORTEX?

VORTEX is the spinning machine developed by Murata Machinery Ltd., and also the yarn made out of these machines.

VORTEX yarn has many applications and enjoys good reputation, thanks to the unique yarn characteristics.

VORTEX yarn is created from new and unique spinning technology

- VORTEX air flow.

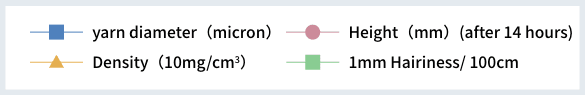

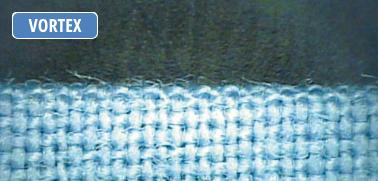

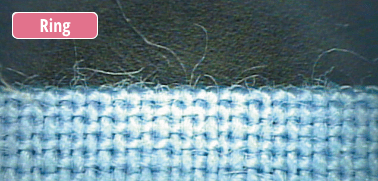

Twist structure of VORTEX yarn

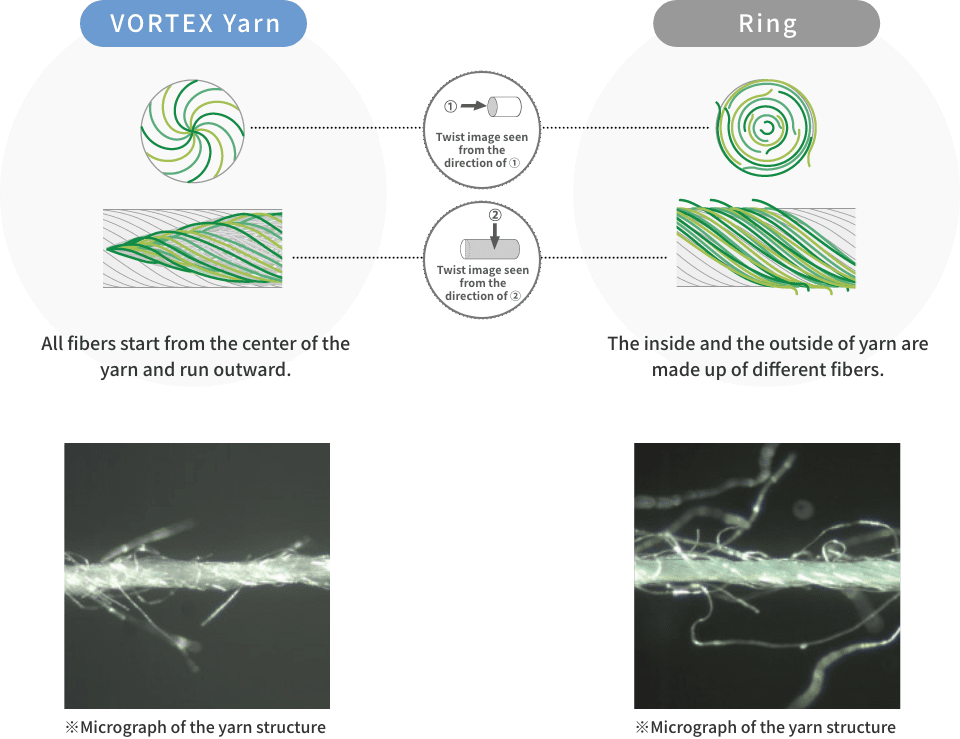

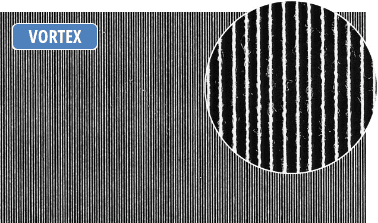

Less hairiness

Each & every fiber in VORTEX yarn tends to be in the center and wraps up to the surface by the air.

This structure leads to the fact about "least hairiness" amongst all spinning systems.

Least hairiness reduces the fluff and dust generation in next process.

Printing and dyeing also take advantage of these characteristics.

Its clear appearance symbolizes the finest characteristics of VORTEX

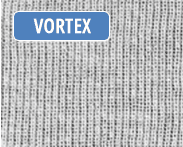

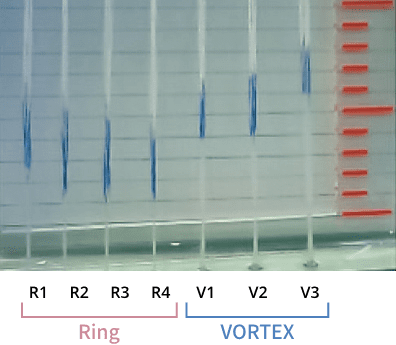

- Photograph 1 : Yarn comparison

-

Ne38/1 (16/1tex)Carded cotton of VORTEX

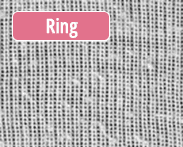

Ne38/1 (16/1tex) Combed cotton of Ring yarn - Photograph 2 : Comparison in Cotton fabric

-

Ne 38/1(16/1 tex)Carded cotton fabric of VORTEX

Ne 38/1(16/1 tex)Combed cotton fabric of Ring yarn

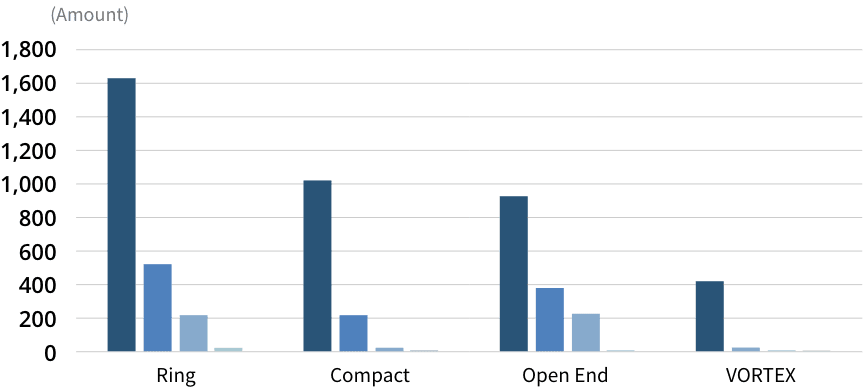

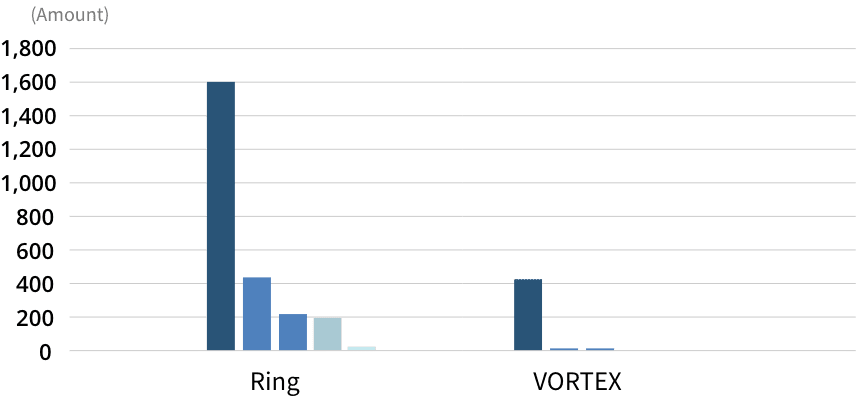

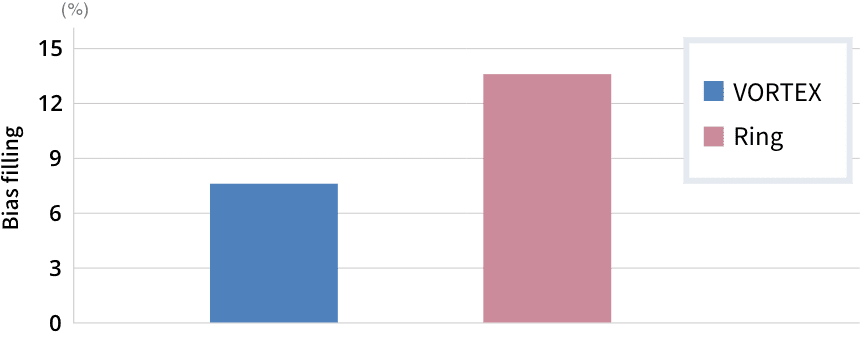

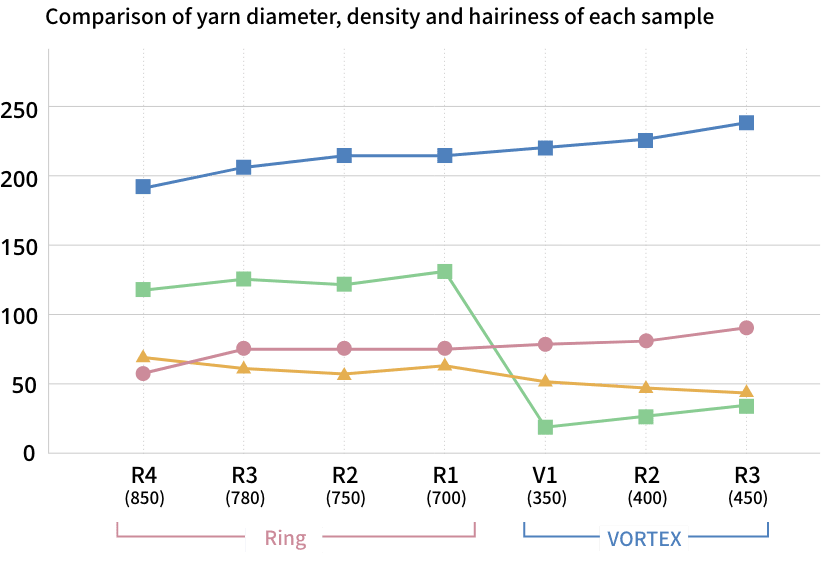

Comparison of hairiness Carded Cotton 100% Ne 30

The number of hairiness per 100m measured by Zweigle G565, Japan

Comparison of hairiness Polyester 100% Ne 30

The number of hairiness per 10m measured by Zweigle G565, Japan

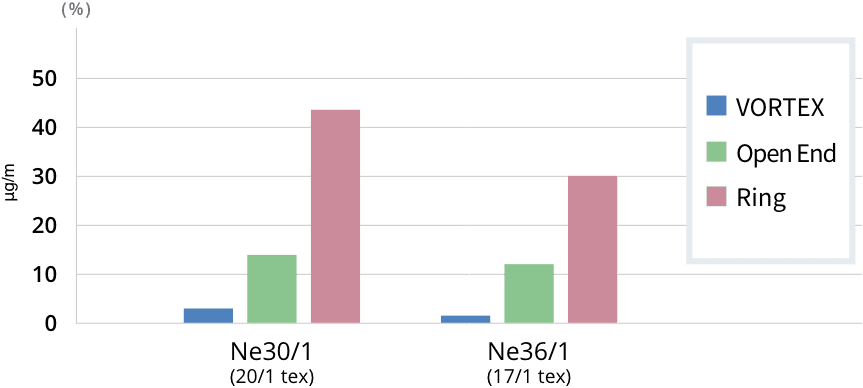

Lint Shedding at cotton 100%

Lawson-hemphil : Lint Tester

Testing speed 150m/min

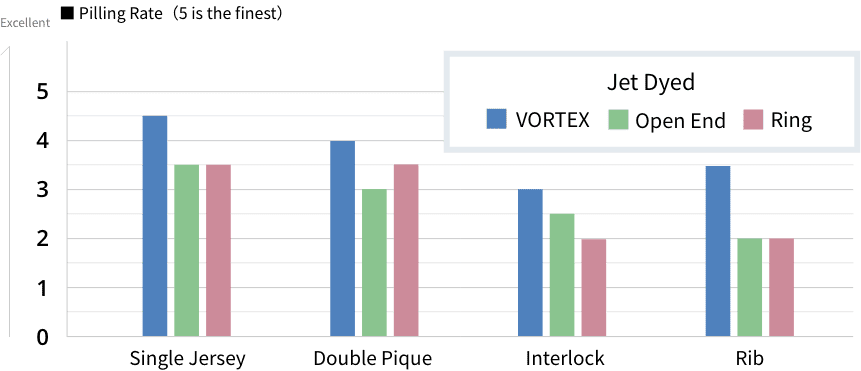

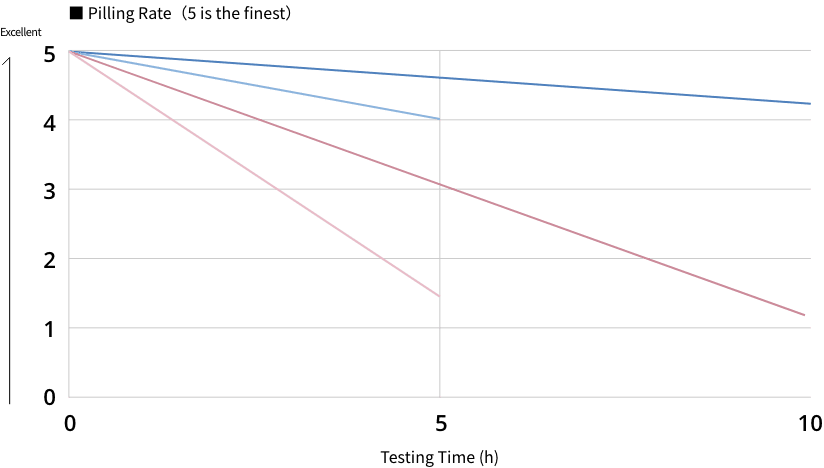

Resistance to pilling

Pilling is a phenomenon where fibers are twisted into ball-like structures by friction between the surface of a fabric and another fabric or object. Because VORTEX has less long hairs and is naturally stable due to its structure, the fibers are secure from movement resulting in reduced pilling.

See the feature of resistance to pilling.

Pilling test results using ICI method

Single Jersey (plating; rayon Ne30/1 +polyurethane 40d)

Pilling test results using the random tumbling method

Single Jersey (plating; rayon Ne30/1 +polyurethane 40d)

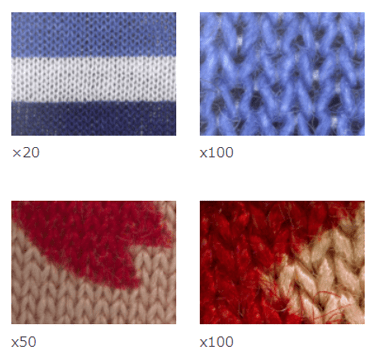

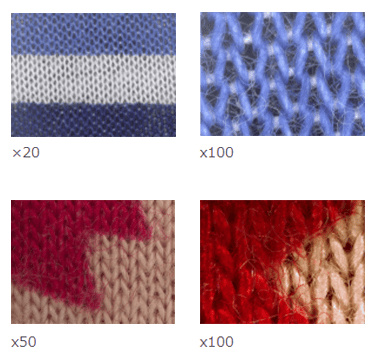

Photograph 1 : Comparison of pilling(Knitting)

Photograph 2 : Comparison of pilling(Weaving)

Comparison of pilling

Carded cotton 100%(US upland)

Single Jersey: Ne 30/1 (20/1 tex), 28 gauge

Double Pique: Ne 40/2 (15/2 tex), 18 gauge

Interlock: Ne 40/1 (15/1 tex), 24 gauge

Rib: Ne 20/1 (30/1 tex), 14 gauge, 1 x 1 rib

Random pilling test 60 min exposure (ASTM), U.S.

Comparison of pilling

Polyester/Cotton blend

SingleJersey: Ne 30/1 (20/1 tex) PE50/C50

200-count sheet: Ne 41/1 (14/1 tex) PE50/C50

ICI pilling test (JIS L 1076)

10 hours for weaving, 5 hours for knitting, Japan

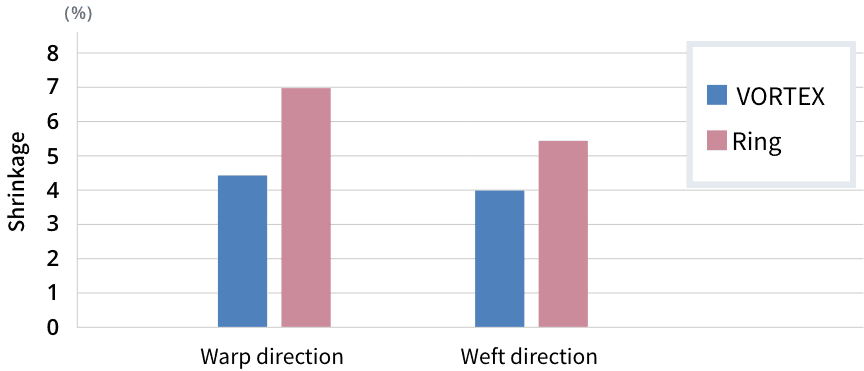

Wash resistance

VORTEX yarn has less lint shedding, less fabric shrinkage, less fabric skew and less color loss caused by repeated wash and dry, when compared with the yarn by other spinning process.

See the feature of wash resistance.

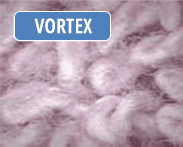

- knitting fabrics (Rib)

Rayon 100% of VORTEX

Rayon 100% of Ring yarn

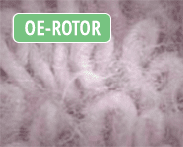

-cotton 100% pile (Terry Towel)

Carded cotton of VORTEX

Carded cotton of OE-Rotor yarn

- knitting fabrics

Single Jersey Ne30/1 (20/1tex) Rayon 100%

Comparison of fabric shrinkage after laundering.

Single Jersey

Combed Cotton 100% Ne40/1 (15/1tex)

JIS L1018D Method, Japan

Comparison of fabric skew after laundering.

Single Jersey

Combed Cotton 100% Ne40/1 (15/1tex)

JIS L1018G Method hang-dry, Japan

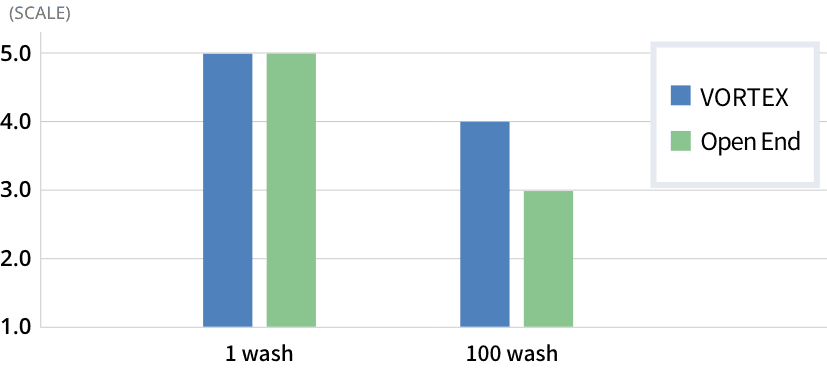

Fabric color retention after laundering (Color Loss)

Polyester 100% Ne12/1 (50/1tex)

AATC Test Method 61, U.S.

5.0=Negligible or no color alteration

4.0=Slight color change

3.0=Noticeable color change

2.0=Considerable color alteration

1.0=Much color alteration

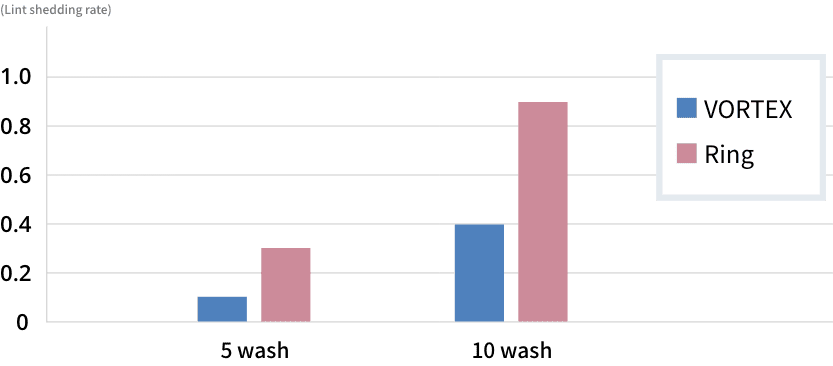

Less Lint shedding

Towels made from VORTEX yarn shed less lint than towels made from Ring yarn.

Additionally, a VORTEX yarn towel maintains its bulkiness longer than that made out of Ring yarn, even after repeated washing.

Cotton 100% pile Ne 20/1 (30/1 tex)

Lint shedding rate: Accumulated lint(tested at Japan Towel Inspection Foundation)

Fine printing

VORTEX yarn has less hairiness, thanks to its unique yarn structure.

This ensures clear printing on the fabrics.

Printed samples

A jersey fabric of Ne30 VORTEX yarn (rayon 92%, polyurethane 8%). A product of Turkey using digital printing.

Weaving, using an Ne40 Rayon yarn of VORTEX. A product made in Brazil with digital printing.

Also, note the clarity of the printed border on the polo shirt. A product of Ne30 100% cotton VORTEX yarn manufactured by an apparel maker in Brazil.

Printed Items

Comparison between VORTEX

printed fabric and RING printed fabric

Single Jersey Ne30 Rayon 100%

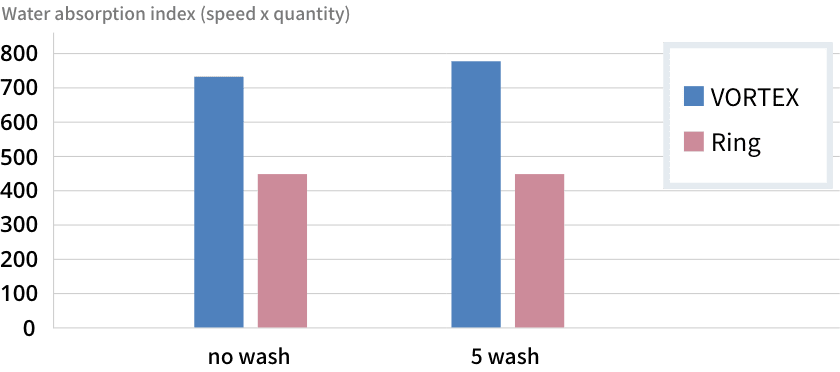

High water absorption

VORTEX yarn has parallel fibers in the center with lot of air pockets.

This structure leads to higher water absorption.

Water absorption index of a towel

Towels made out of VORTEX yarn has better water absorption capability compared to that of Ring spun yarn.

Cotton 100% pile Ne 20/1 (30/1 tex)

Absorption index: according to the absorption test of the High Absorption Fabric Council

(tested at Japan Towel Inspection Foundation)

Comparison of water absorption with Rayon yarn

Rayon 100% Ne30