It’s Unique

VORTEX is the brand of spinning machine

and yarn from the machine

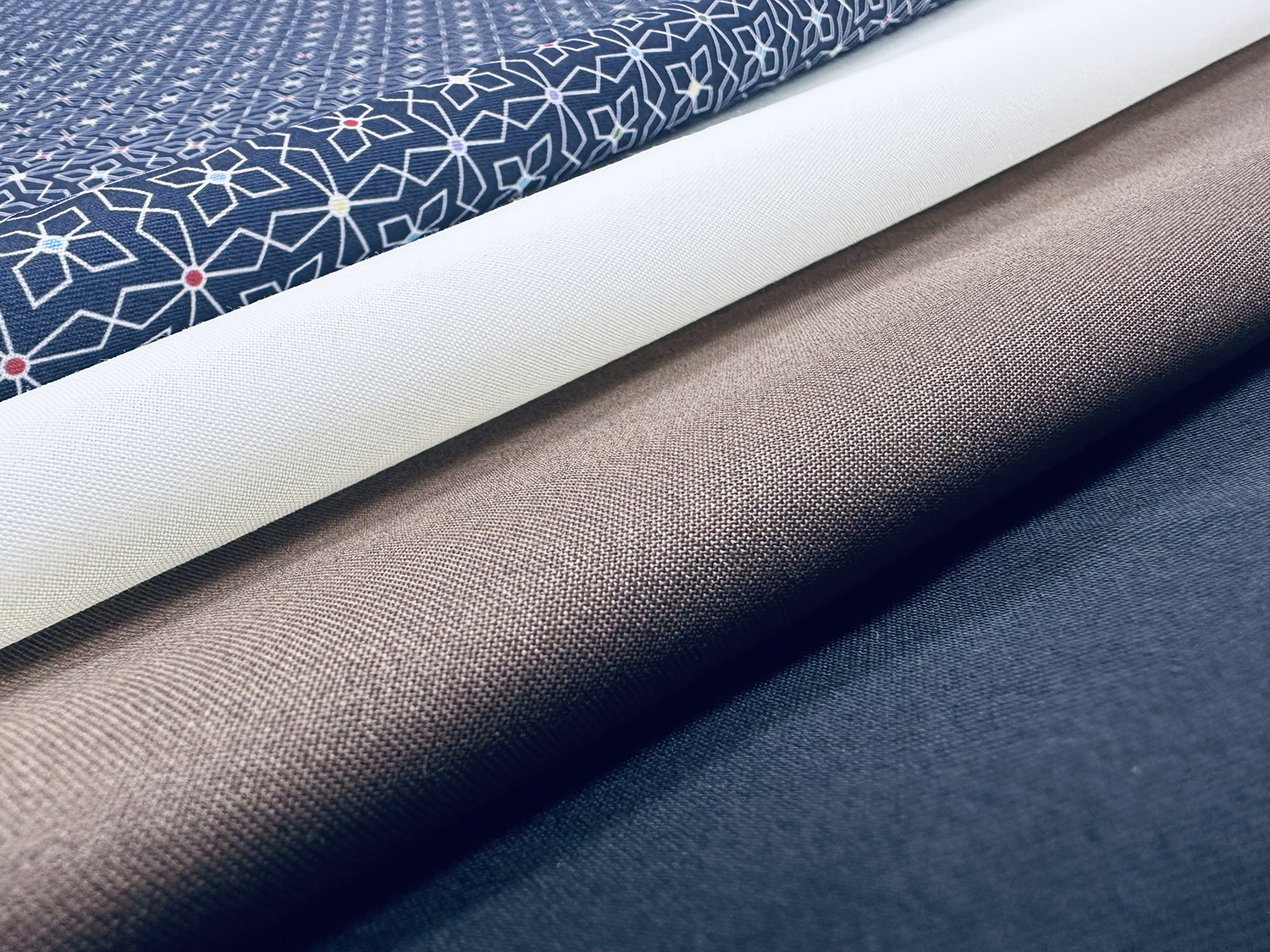

FEATURE

-

MACHINE AND HISTORYAbout VORTEX Spinning Machine

MACHINE AND HISTORYAbout VORTEX Spinning Machine -

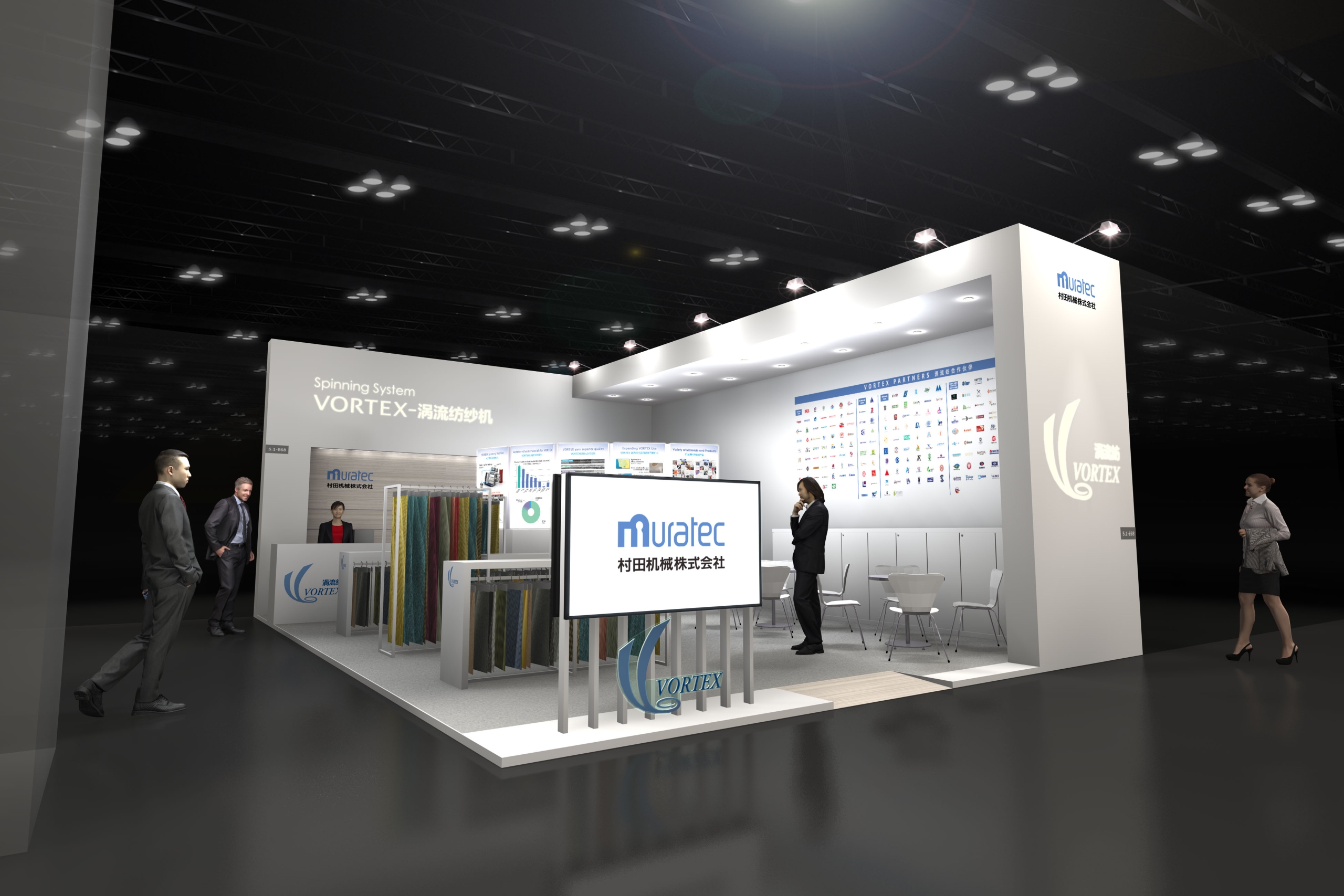

VORTEX PARTNERSVORTEX Partners List

VORTEX PARTNERSVORTEX Partners List -

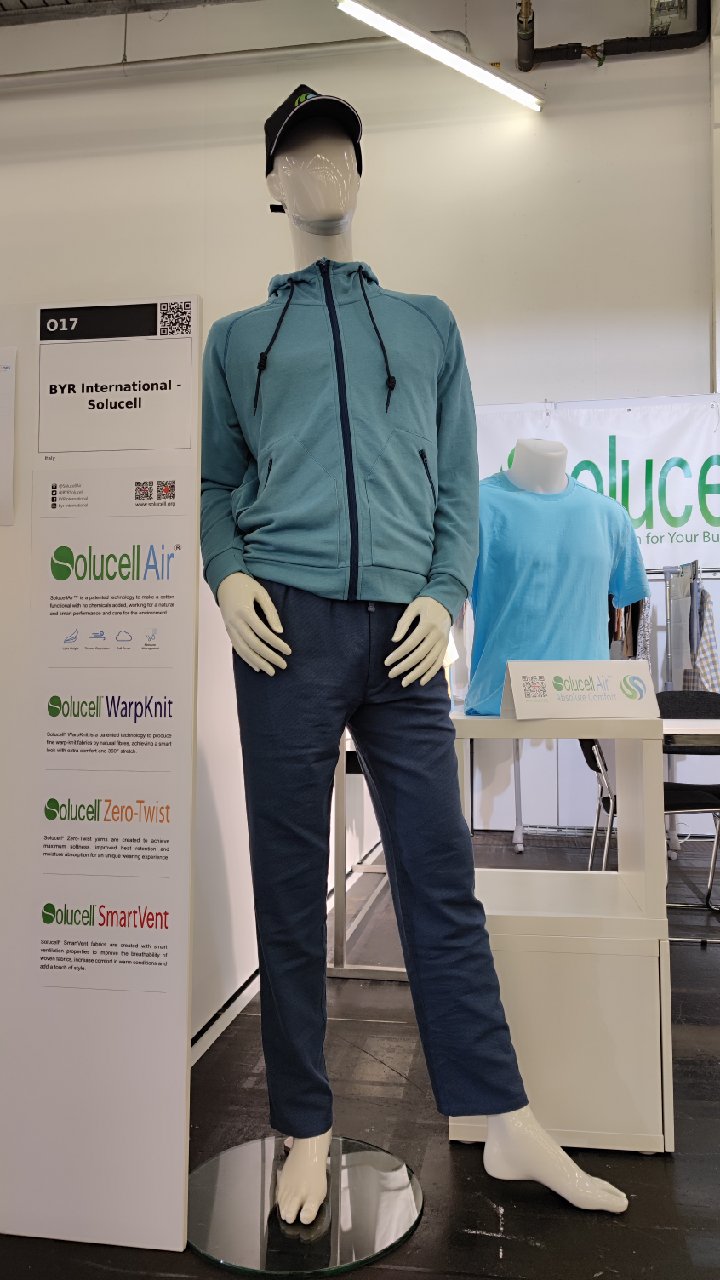

SUSTAINABILITYVORTEX can help

SUSTAINABILITYVORTEX can help -

SHOWROOMAbout the showroom

SHOWROOMAbout the showroom -

ABOUT USMurata Machinery

ABOUT USMurata Machinery